Seit mehreren Jahren beobachten wir die Entwicklung im Bereich Schutz empfindlicher Elektronik gegen Umwelteinflüsse.

Seit Jahrzehnten bewährt hat sich 2-Komponentenverguss mit Polyurethan oder Epoxydharz.

Wärmeableitung, Isolation, Feuchtigkeitsschutz sowie mechanische Robustheit werden durch den Verguss verbessert.

Der Zeitaufwand, die Notwendigkeit eines Gehäuses, der Einsatz von Gefahrstoffen in der Produktion spricht gegen diese Technologie.

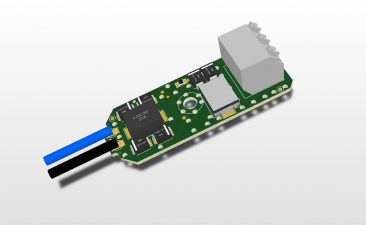

Das Niederdruckspritzverfahren mit Polyamid-Granulat bietet zwar nur eine geringere Wärmeableitfähigkeit als Vergussmaterialien und geringere mechanische Festigkeit als ein klassisches Gehäuse, gewährleistet aber eine schnellere Verarbeitung und höhere Umweltverträglichkeit.

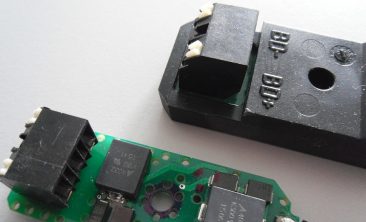

Seit März 2016 bieten wir unseren Kunden komplett ummantelte Hotmelt-Baugruppen sowie nach wie vor den Einsatz des Verfahrens in der Kabelkonfektion für Zugentlastungen, Abdichtungen, Formgebung von konfektionierten Steckern und Anschlüssen an.

Schreibe einen Kommentar