Wire strands, wire harness and fully assembled cables and cable looms can be manufactured in a wide range of specifications and in any desired volume.

UL/CSA-approved cable assemblies are available in category ZPFW in accordance with UL File E153662.

Variety of solutions

- Wire strands to VDE and UL/CSA requirements, from 0.06 to 95 mm² and from AWG32 to AWG0

- Multi-wire cables, screened, screened in pairs or unscreened to VDE and UL

- Flat-band cables with 2.54 to 0.65 mm pitch

- Coax cables

- Insulation and heat-shrink tubes, various cable protection systems

- PVC, silicone, PUR, rubber and other materials

Cutting, stripping and sheath removal

- Automatic and semi-automatic cutting, stripping and sheath removal of cables and wire strands.

- Automatic cutting to size of tubes, flat-band cables and other materials.

- Automatic stripping of wire strands with high-speed precision strippers from Schleuniger, GLW or other manufacturers (if stripping cannot be performed during cutting to size).

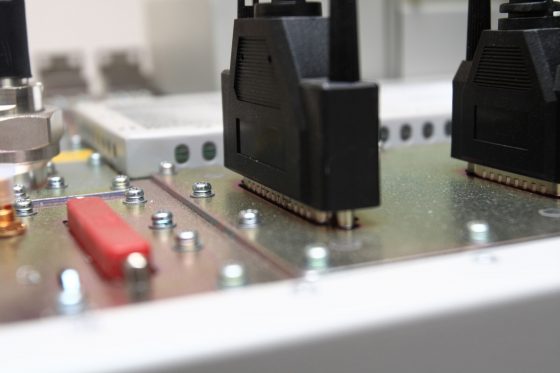

Cable assembly

Equipment used for affixing and crimping contacts and connectors:

- About 100 quick-change tools for automatic contact application

- Various die sets for insulated and non-insulated loose contacts for processing with pneumatic and electric crimping presses

- Stripper-crimper for processing wire-end ferrules (loose or in strips)

- Processing tools for IDC connectors for flat-band cables or single strands

- Lead-free or (if desired) leaded tinning and soldering

Tests & inspections

Cable assemblies are tested by means of programmable electric cable testers which include features such as high-voltage, insulation and component testing.

The crimp quality is assessed by taking accurate measurements, pull force testing and micrograph cross-section analysis in accordance with applicable standards and in-house procedures.

Identification

State-of-the art printing systems enable direct marking of cables and wires or the use of printed cable labels or printable heat-shrink tubing.